Types and Usage

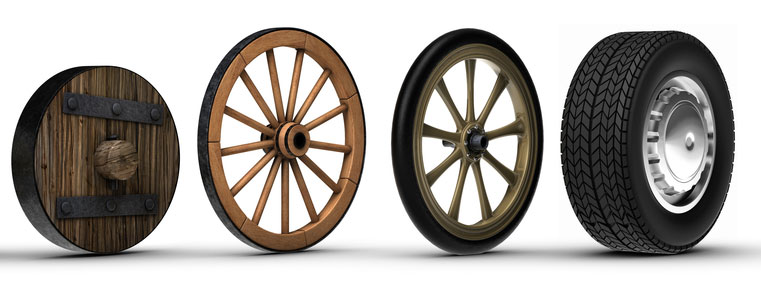

A Wheel is a round object which rotates in a circular motion. Wheels are often attached to machines to make getting around and transporting things easier.

There are mainly 11 types of Wheels.

1. Forged Steel: Fine grain forged steel Wheels are precision machined to offer the greatest load capacity, impact strength and rollability. Precision tapered bearings compliment the characteristics of these wheels.

2. Cast Iron: Precision machined cast iron wheels feature premium Class 30 gray iron with a heavy duty cross sections. These wheels are excellent for high heat applications.

3. Ductile Iron: Ductile iron wheels feature many of the same characteristics of cast iron; however, the ductile iron wheel has higher tensile and yield strengths. Resists breaking or chipping.

4. Polyurethane: Polyurethane wheels feature a higher capacity material than rubber, provide longer wear, and will not damage your floors like cast iron or steel. A wide variety of liquid cast polyurethane wheels are offered.

5. Mold On Rubber: Rubber offers a cost effective alternative to polyurethane while providing a cushioned and quiet ride for the product being transported. Neoprene and high load compounds are also available.

6. NyTec-MD: NyTec wheels provide a tough material which can handle up to 80% the weight of steel or cast iron.NyTec has excellent load carrying capacities and resists corrosion. NyTec provides a long wearing material and is especially suitable when maintenance is an issue.

7. Phenolic Resin: Phenolic resin wheels offer a load carrying capacity approaching that of cast iron or steel wheels. Phenolic resin wheels are a cost effective alternative with increased rollability and will not damage floors.

8. V-Groove: “V” grooves are machined from either cast iron or hot forged steel wheels. V-grooves work on track or off track and are essential where precise alignment or indexing of equipment is necessary.

9. Flanged: Single and dual-flanged wheels operate on a rail for locating fixtures in a precise position for indexing through a work cycle. Premium cast iron and steel is used for the wheel material to provide high strength and long wear.

10. Pneumatic: Pneumatic wheels offer the highest cushioning, shock absorbing caster/wheel, without moving to a more expensive spring loaded caster. Capacities of pneumatics are limited due to the soft cushioning characteristics of the wheel.

11. Drive/Keyway: Drive/Keyway wheels are offered from 3” to 18” diameter. Bore sizes from 1/2” to 2-7/16”. Drive surfaces of poly, rubber, or steel. Excellent for power transmission applications.

Tags: Be Axis